This is going to be a series of posts on what I’ve learned about spokeshaves and travishers over the years. These are some of my favorite and most used tools and I think a deep dive is well worth the effort. I am also going to start making some posts that are only available to the supporters of the site, I hope you will consider supporting me as I build this resource.

I made my first travisher when I came across a few curved blades in the bargain bin at Garrett Wade on Sixth Ave in New York. I was getting started in chair making and had seen pictures of a travisher, but never one in the wild. The blade was the style found in wooden spokeshaves with tangs.

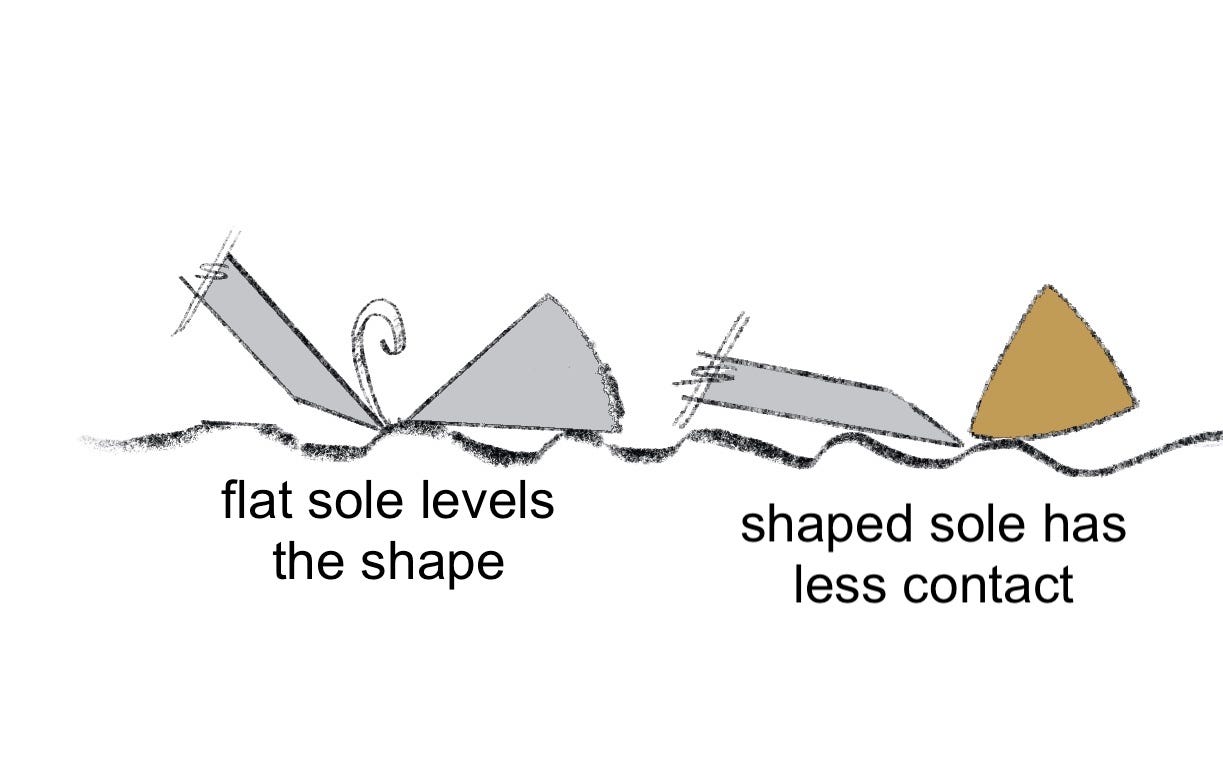

I think that there is some confusion about the tang style blades. First of all, yes, they are a pain to maintain and sharpen because depending on your set up, the tangs can get in the way when grinding and honing. I will go into solutions to this, my own was to eliminate the tangs altogether. In some places, I’ve seen it advised that the blade can be adjusted by tapping out the tangs a bit, but I think this fundamentally misses the way this tool works. The real adjustment is built into the shape of the sole. You can adjust the depth of cut by rolling on the sole slightly forward or back while moving the tool. This is this tools superpower and it frustrates me when I see folks go to great lengths to make separate adjusters.

Having the sole shaped this way makes this tool a carving tool, capable of great speed and accuracy during carving as I explain in the video below.

Here is another view of what I am describing.

When I made my first travisher, I studied the wooden spokeshaves and modeled my tool after the shaped sole. So for me, I always push my travisher to get the most control over the depth of cut.

There are metal spokeshaves with curved soles, but the way that the shape interacts with the blade, it’s really more like a forshortened spokeshave that allows me to reach into tighter curves and fair them with ease, but the blade orientation and shape of the sole doesn’t afford the same easy variability of depth that the shaped sole on my wooden shaves does. As I noted, there are lots of shaves that I’ve seen with flat soles and mechanics for adjusting, but they forfeit the flexibility and speed when carving.

Hopefully, this sets the stage for understanding the travisher, which has been a favorite tool and obsession for the last 20 years.

I tell ya, Pete, and I don't care that I'm going to sound like a fan boy: You are a rare combination. You are great at a LOT of the "doing" - what do we got? At least drawing, painting, sculpting, carpentry (rough and fine), chair building... but you are also a very effective teacher. Again, sorry if it embarrasses you to hear, but you really are a gifted teacher.

I taught at the university for a few years and it just drove home how stressful it is to learn. On multiple levels.

My current hypothesis is that the best teachers address that stress/anxiety in their method.

You're not only capable and clear, but also very calming. I think it's about empathy.

Hi Pete,

It is a rare thing for someone to be able to do complex things with ease. More rare is being able to think about what you are doing with depth and nuance. But the most rare is being able to relate that to someone else in ways they can understand and put to good use. You are all those things. You would have made an great surgeon. I came to woodworking after a stint as a Professor at the Boston University School of Dental Medicine and I know the value of a great teacher. You are a great teacher and those of us who have been taught by you are all the better for it.