Rocker Layout

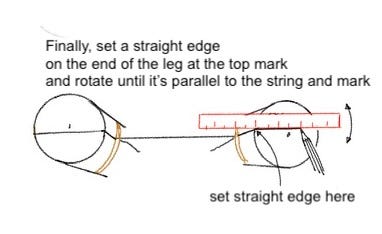

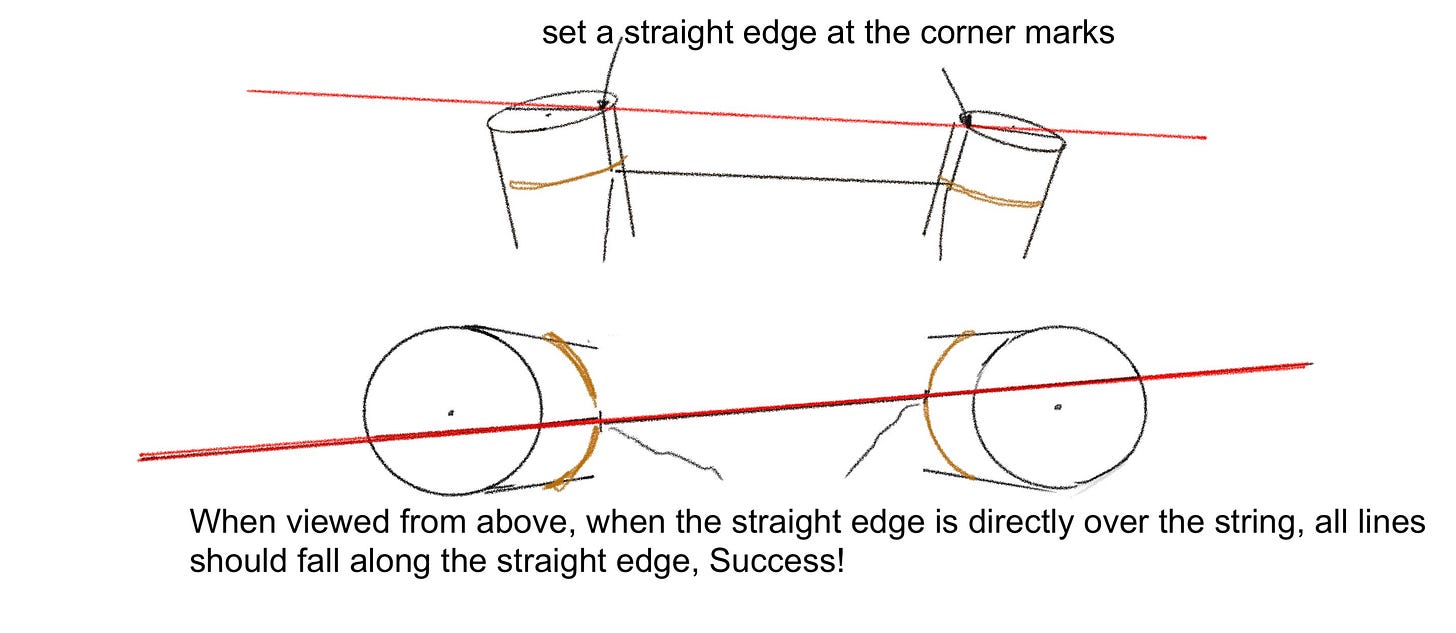

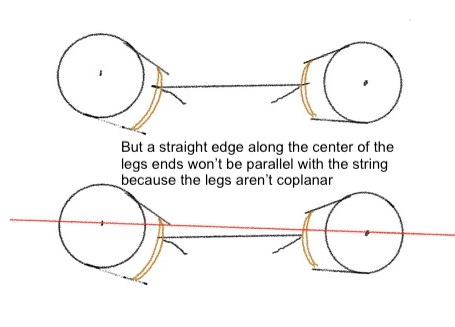

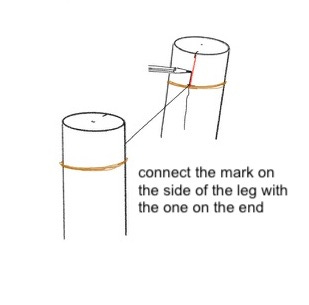

If you are cutting rocker slots, especially by hand or a simple router jig, it will require laying out lines that follow the axis of the rockers through each leg. This is a bit tougher than it might sounds because the legs are rarely in the same plane. So as I mention in the videos, you will need to split the difference by offsetting the slots at the ends of the legs to maintain strength at the depth of the slots. Here is a sequence of drawings that shows a method that I’ve used for years. After running through it a few times, you will also get a better mental image of the issues that arise when a straight channel passes through legs that aren’t coplanar.

Time to check your work.

Once I’ve established these two lines on each leg, I can use them as centers to layout whatever thickness I will be sawing. Usually, I use the lines to create a path for a router to follow as I show in the Rocker article I did in Fine Woodworking way back.

I love solving sticky problems with string and rubberbands, especially when I don’t have to use numbers and bevel squares. I hope you find this helpful, lemme know

The feb issue 2011 and the subsequent issue, it’s a two parter

Hi Pete. I have one of your slot cutting jigs that I got from Dan M. when he came to teach me the contemporary rocker. I've made several thus far, but on the last two I've had trouble with cutting the slots with the router. I've tried feeding the router in both directions and sometimes I get torn up slots and other times not. I tried feeding the bit cutting in the opposite direction of the rotation of the cutting edge. I'm running the router at 25,000rpm, and taking four passes to get to the final depth. Can you advise me as to which direction the cutter should be rotating to get the best cut or what I might be missing on this? Thanks!