What's the Problem?

The tools I’ve made have all begun with problems. I don’t know if it’s just me, but I always hated setting and organizing spring calipers. I suppose that was enough to keep my eyes out for another solution. As you can see, it took a lot of iterations and cranky little experiments before getting to the final product. It’s a long process of problem solving, learning about production methods, redesign and cost analysis. It’s very time consuming and expensive, but I really enjoy it. In the end, the truly rewarding moment is when another person expresses that they appreciate the difference the tool makes in their own workshop.

My recent dive back into travishers was brought about by a few problems. One is availability. I have 8 Claire Minihan travishers, which are based on my design.

I bought all but one of mine (thanks for the b-day gift Claire) and they are well worth it. But Claire isn’t producing them full time right now and I haven’t been able to recommend another comparable tool. It’s been frustrating for both me and my students.

The next problem is really about another tool, the inshave. Lots of folks struggle with this tool when removing lots of wood on a shapely seat. I’ve been wanting a tool that could hog off material and do fine cuts to lessen or eliminate the need for the inshave. (btw, Jason Lonon, the excellent blacksmith, is offering an inshave that he says eliminates the need for a travisher!, the choice is yours)

The final problem is that many folks are turning to hardwood seats (thanks Chris) and need a hardy tool that involves the arms more than the hands when pushing and controlling the tool. Even on a softwood seat, I find the increased involvement of my arms less tiring when hogging off material.

Here are a few pics to highlight how seeming subtle design changes can affect the use and performance of a tool.

First of all, here is a handle design you might be familiar with. The shape and position of the handle direct the force down and forward to a point just ahead of the blade, making the use very natural and effective. This is no accident, even in the hands of a novice, the tool “wants” to work correctly just because you grab the handle and push.

Here is Claire’s travisher, where the control and drive comes mostly from the thumbs which rest on small pads on either side of the throat.

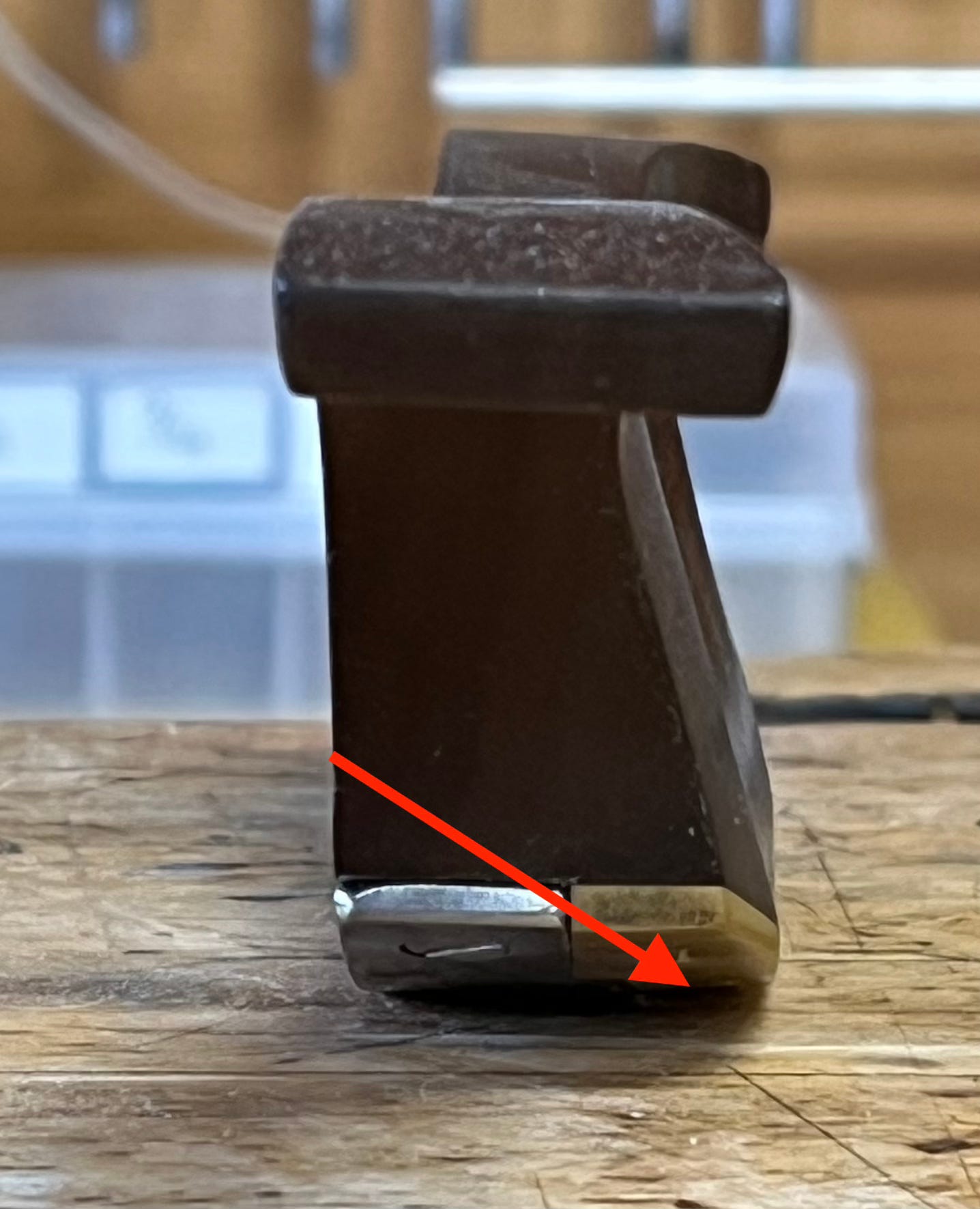

Here is the prototype T2, the force comes from the heel of the palm on the handles. This engages and align the arms and wrists with the tool.

Here is a short video showing the difference between the two travishers in use

A well designed tool should be effective and intuitive. The final part of the tool design process is to put the it in the hands of a new user and observe. I worked to complete the T2 design before Handworks, knowing that there is no better place to get the tool into willing and eager hands. I always learn so much from this part, as I stand back and observe, with poorly hidden intensity, as someone steps up to use it for the first time. It’s an easy trap to make a tool and declare it useful because the maker and other experts say so, but the true test is in the hands of the beginner. When they find it natural and easy to use, the feeling of joy and relief is mutual.

Thanks Pete. Good advice.

The Stanley plane in your blog is the perfect example of excellent direction of force to its blade that we can all understand. There are modern plane makers, Veritas and Clifton come immediately to mind, that have a more upright and straight handle ( tote) that is not near as comfortable to use as is a vintage Stanley plane’s curved handle is, at least to me. Others more experienced than I am have made the same observation. This is true with many tools including Sloyd knives, chisels, saw totes etc. The ergonomics for grip comfort and the efficient use of hand pressure are very important. Just because a tool looks really good, does not mean it will be as comfortable when in use. Try before buying is a good thing.

Pete, I can't wait to see the T2...and if I can take a decent shaving with it, you'll know you've made a tool for everyone! :-) It gives me joy to read your absorption in the creation and refinement of tools...I am so grateful to have the privilege of being one of your many students.